Assembly

The assembly process for polyurethane products follows these main steps:

- Preparation of parts

- The moulded polyurethane items are inspected to ensure compliance and absence of defects. The surfaces are also cleaned to ensure good adhesion between the components.

- Workstation setup

- The assembly area is prepared with the necessary tools and materials, such as adhesives, screws, supports and other accessories required for assembly.

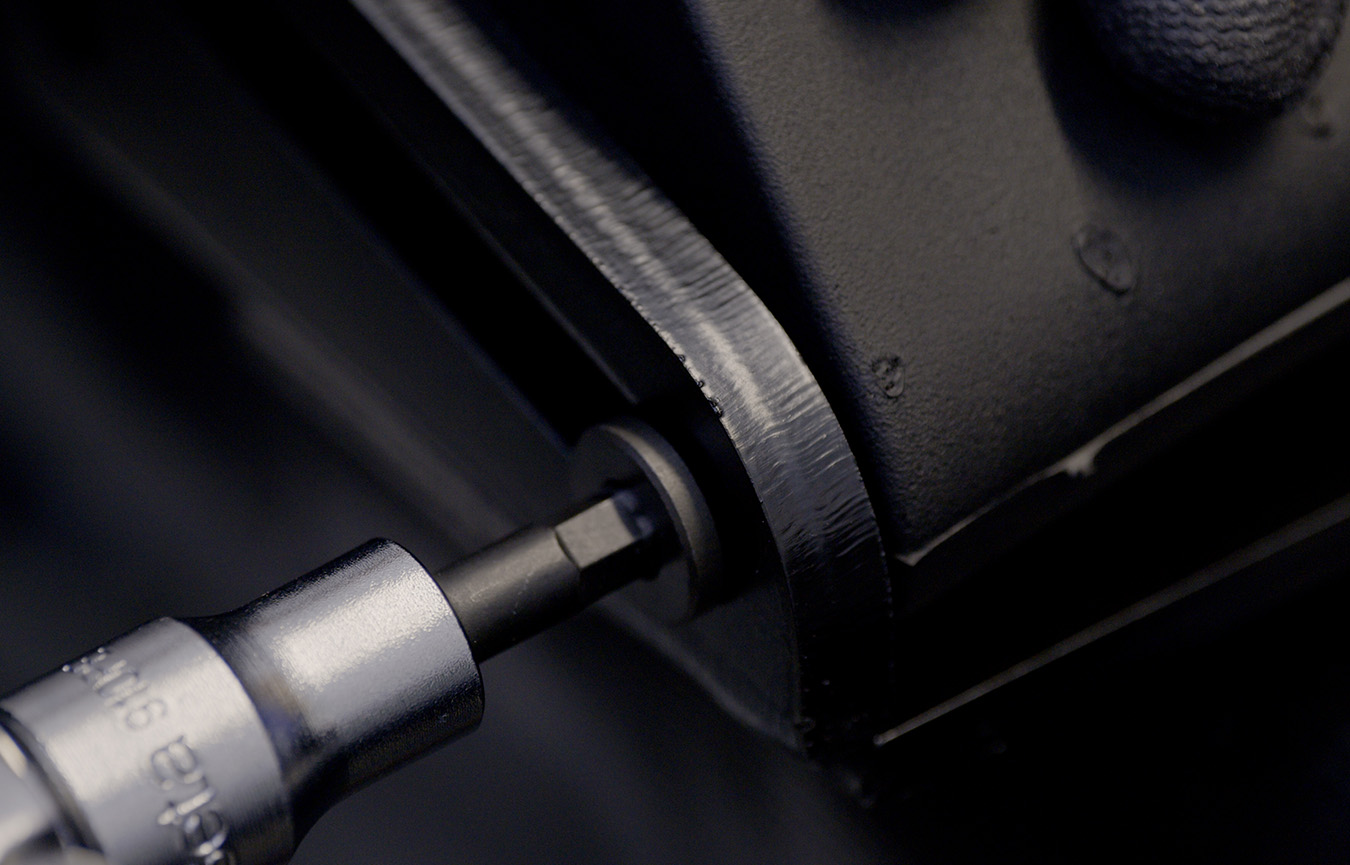

- Joining components

- The moulded polyurethane parts are joined using the most appropriate method: chemical adhesives for durable, invisible bonding; mechanical fastening with screws, rivets, or clips; or interlocking designs for snap-fit assembly.

- Final inspection

- Once the process is complete, the product is checked to ensure secure and functional connections.

- Finishing and customisation

- The assembled product may undergo additional processes such as painting, decorative applications, or surface treatments.

- Packaging and storage

- The finished products are securely packaged and stored, ready for delivery.

Would you like to discuss your next project?

We will provide you with a quote within 24 hours – simply send us your STEP file.

We value your ideas and have the expertise and experience to help you bring them to life.