Research and Development

Research and Development is a cornerstone of our company. Innovation is key to remaining competitive and often provides a significant boost to production. The main stages of our R&D process are:

- Market needs analysis

- Identification of market trends and customer demands. Study of emerging technologies.

- Materials development

- Research into new polyurethane formulations to improve properties such as strength, flexibility and sustainability. Testing with additives, expanding agents or colourants to customise the material.

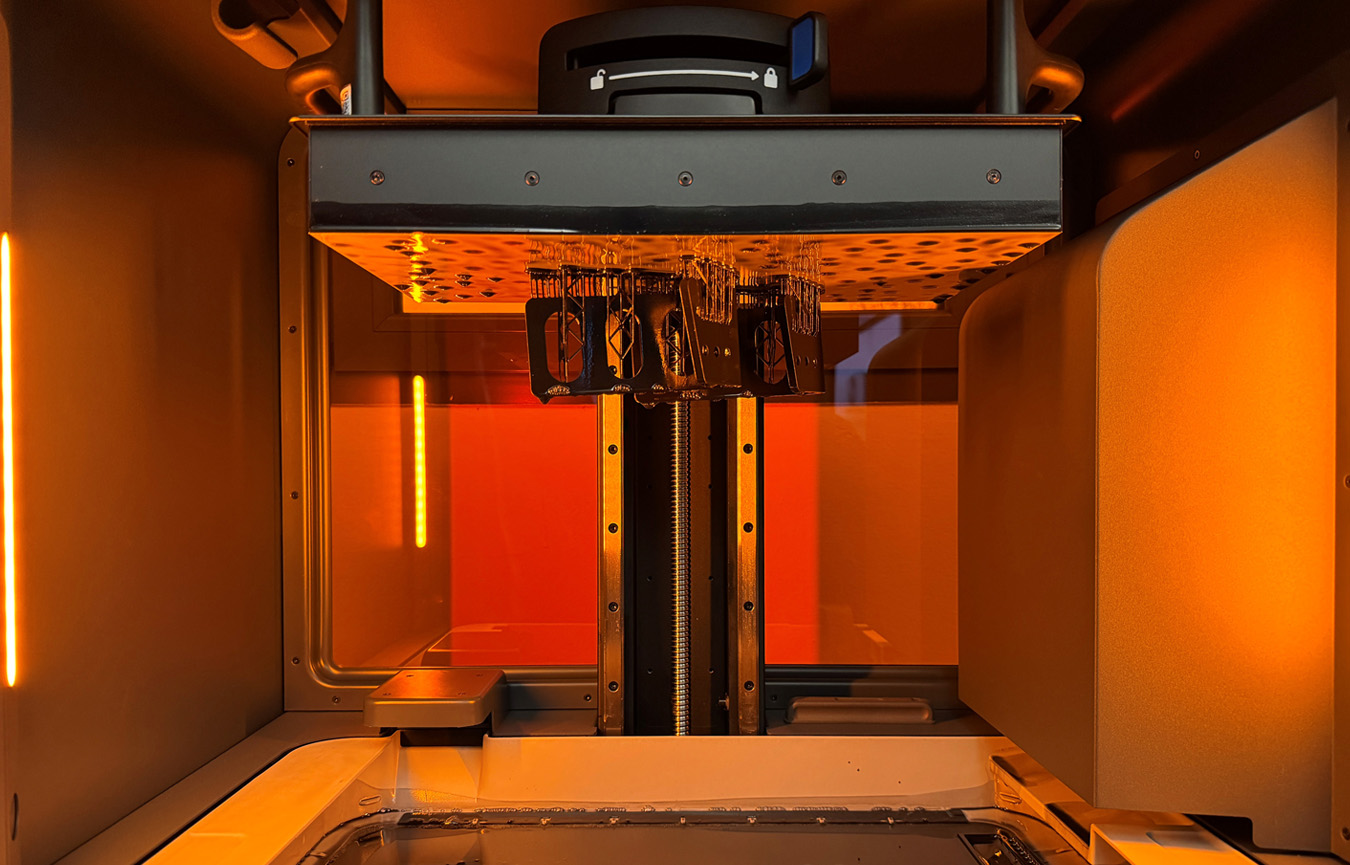

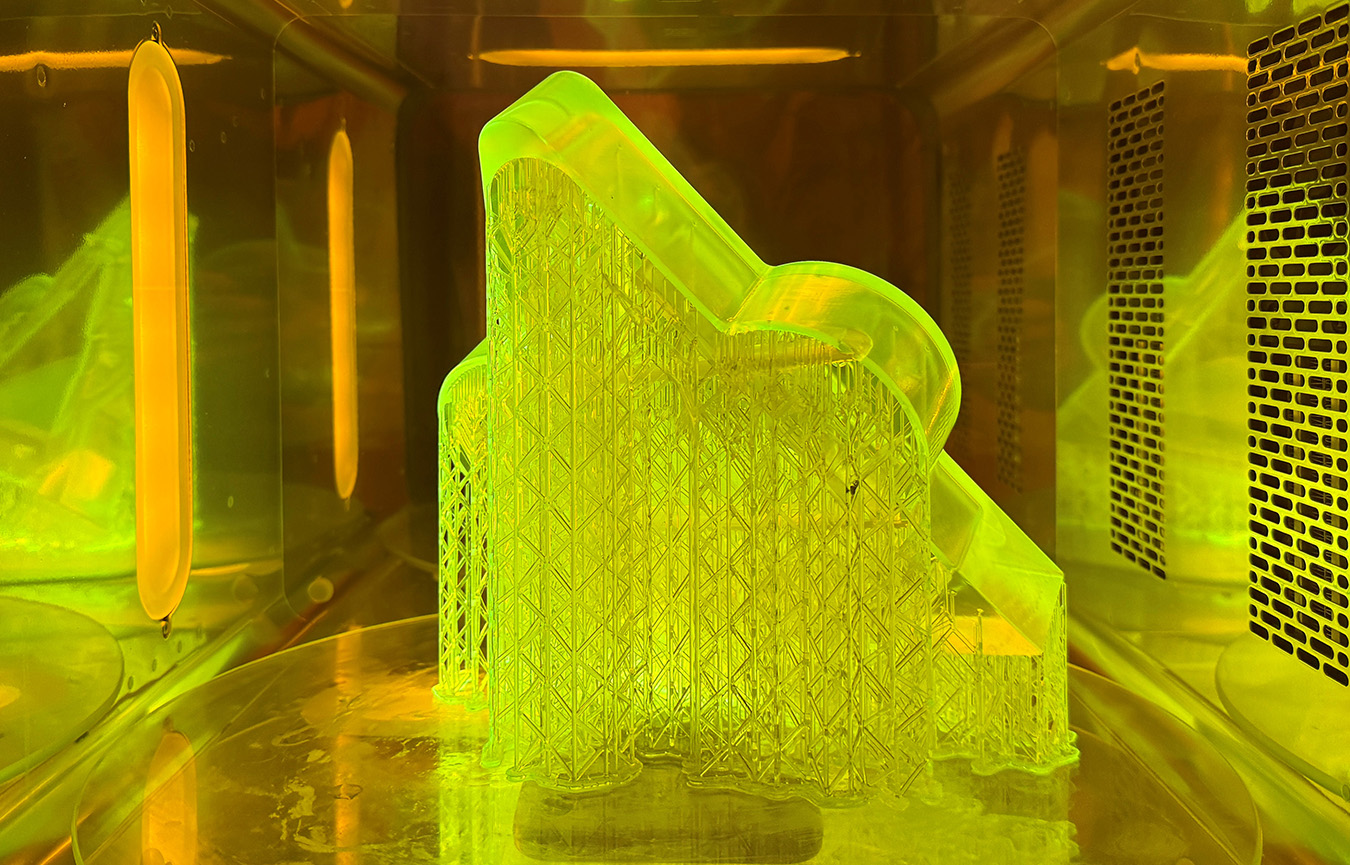

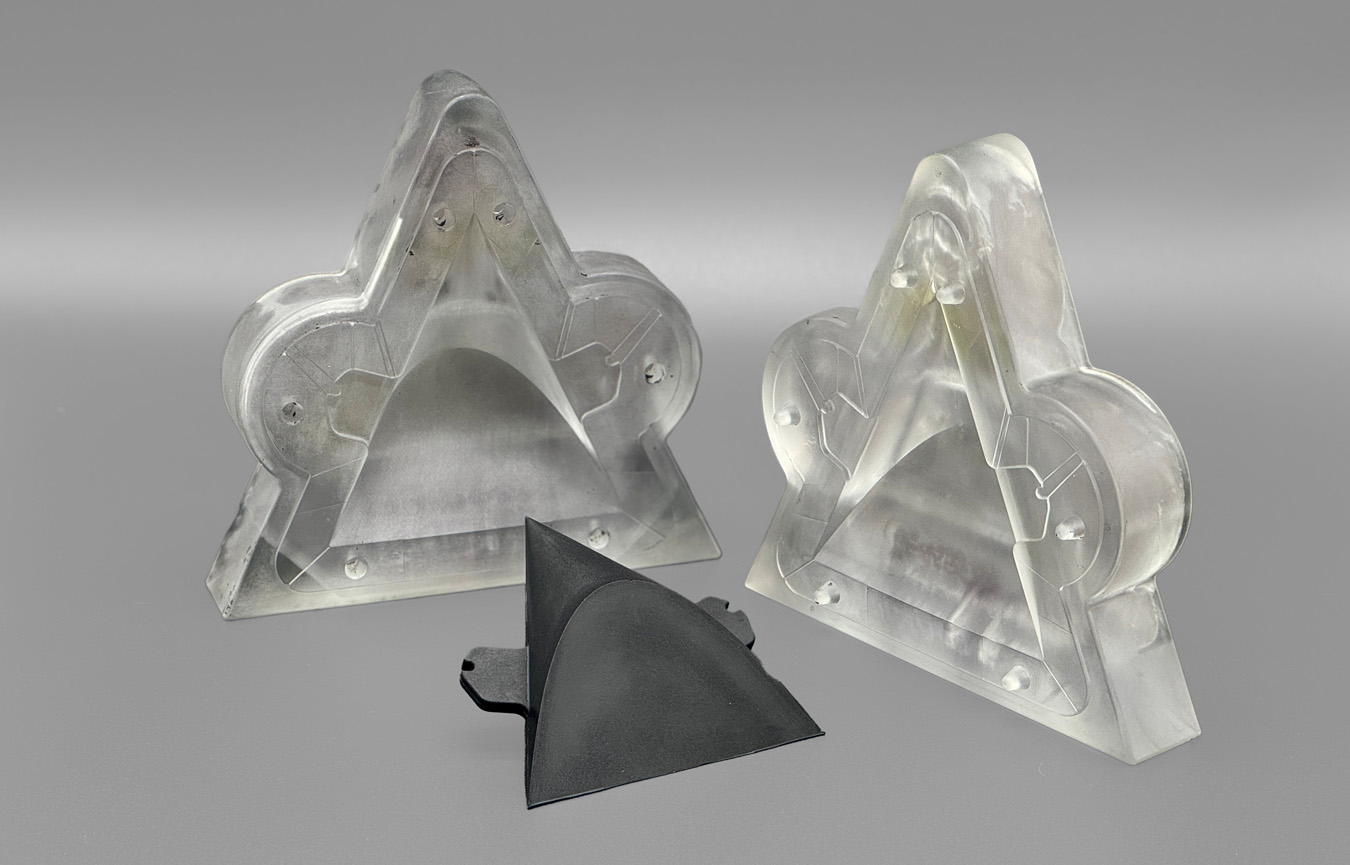

- Design and prototyping

- Creation of designs and 3D models for new products. Production of prototypes using moulding to evaluate shape, functionality and quality.

- Testing and evaluation

- Assessing resistance, durability, chemical behaviour, and mechanical properties of new products, as well as compatibility with specific assembly techniques or environmental conditions.

- Process optimisation

- Experimenting with new moulding methods and production technologies to reduce waste and increase efficiency.

- Sustainable innovation

- Exploring eco-friendly alternatives to traditional polyurethane, such as biodegradable or recycled materials, and developing low-impact production processes.

- Working with partners and suppliers

- Partnerships with the R&D departments of suppliers to access advanced knowledge. Participation in collaborative research projects to achieve economies of scale.

- Feedback and iteration

- Collection of feedback from customers or internal teams to continuously improve products and processes. Repetition of the design and formulation to obtain the best results.

Our R&D activities enable us to develop innovative, high-quality products that effectively meet market demands.

Would you like to discuss your next project?

We will provide you with a quote within 24 hours – simply send us your STEP file.

We value your ideas and have the expertise and experience to help you bring them to life.