Moulding

The moulding process for polyurethane products follows these main steps:

- Mould preparation

- The mould is cleaned and coated with a release agent to facilitate the extraction of the finished piece without damaging it.

- Polyurethane mixing

- The raw materials, typically isocyanate and polyol, are blended in precise ratios. Additives such as colourants or blowing agents may also be incorporated at this stage.

- Pouring into the mould

- The mixture is quickly poured into the mould before the chemical hardening process begins. In some cases, a closed mould is used, which is compressed to obtain the desired shape.

- Polymerisation

- The chemical reaction between the polyurethane components generates heat and allows the material to harden and solidify. This process can last from a few minutes to several hours, depending on the type of polyurethane and the technical specifications.

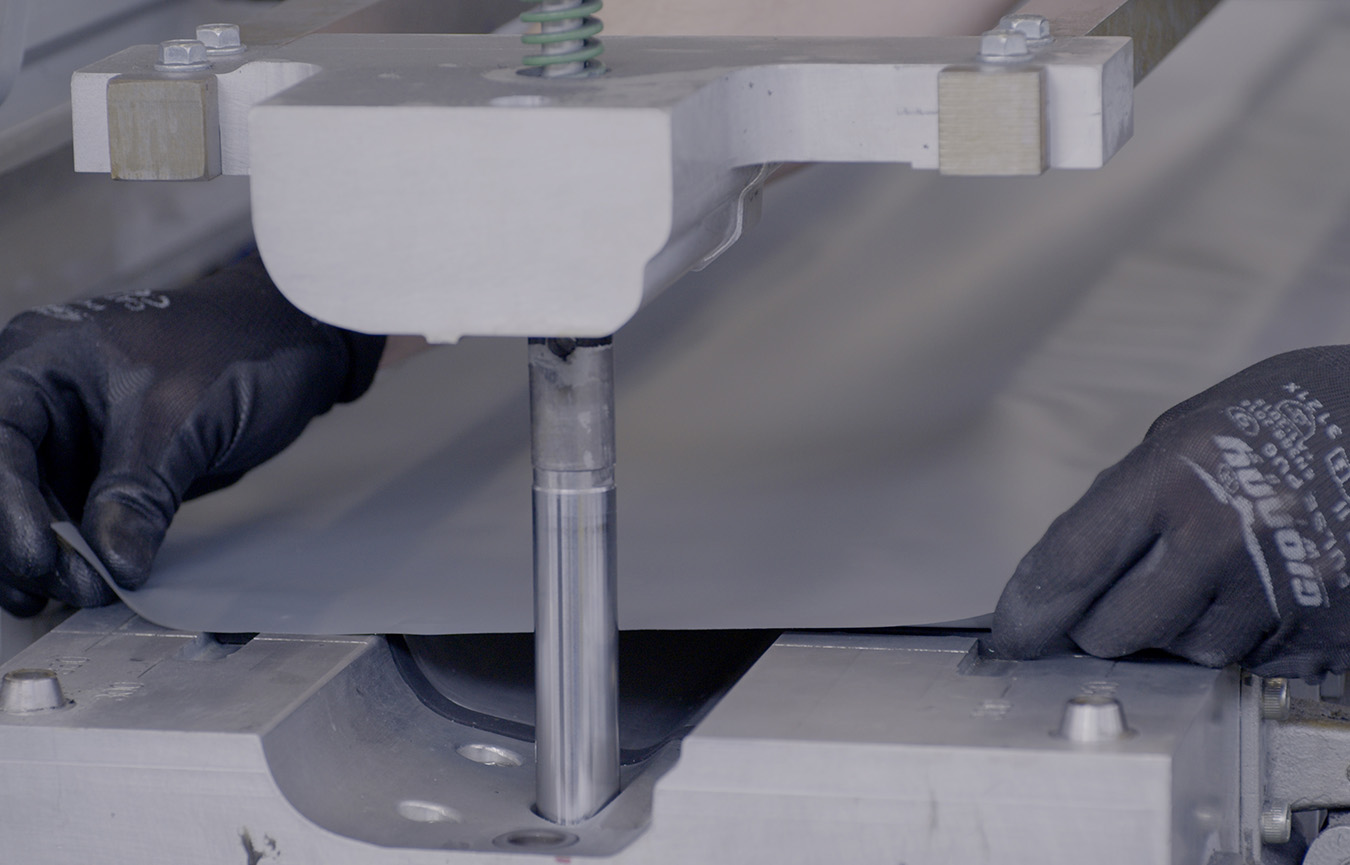

- Extraction

- Once solidified, the part is carefully removed from the mould to avoid deformation or damage.

- Finishing

- The moulded part undergoes final operations such as deburring, smoothing, or surface treatments to achieve the desired result.

Moulding with 3D printing

How digital technologies are transforming polyurethane moulding

This approach reduces time and costs while ensuring maximum flexibility at every stage of the project.

Would you like to discuss your next project?

We will provide you with a quote within 24 hours – simply send us your STEP file.

We value your ideas and have the expertise and experience to help you bring them to life.