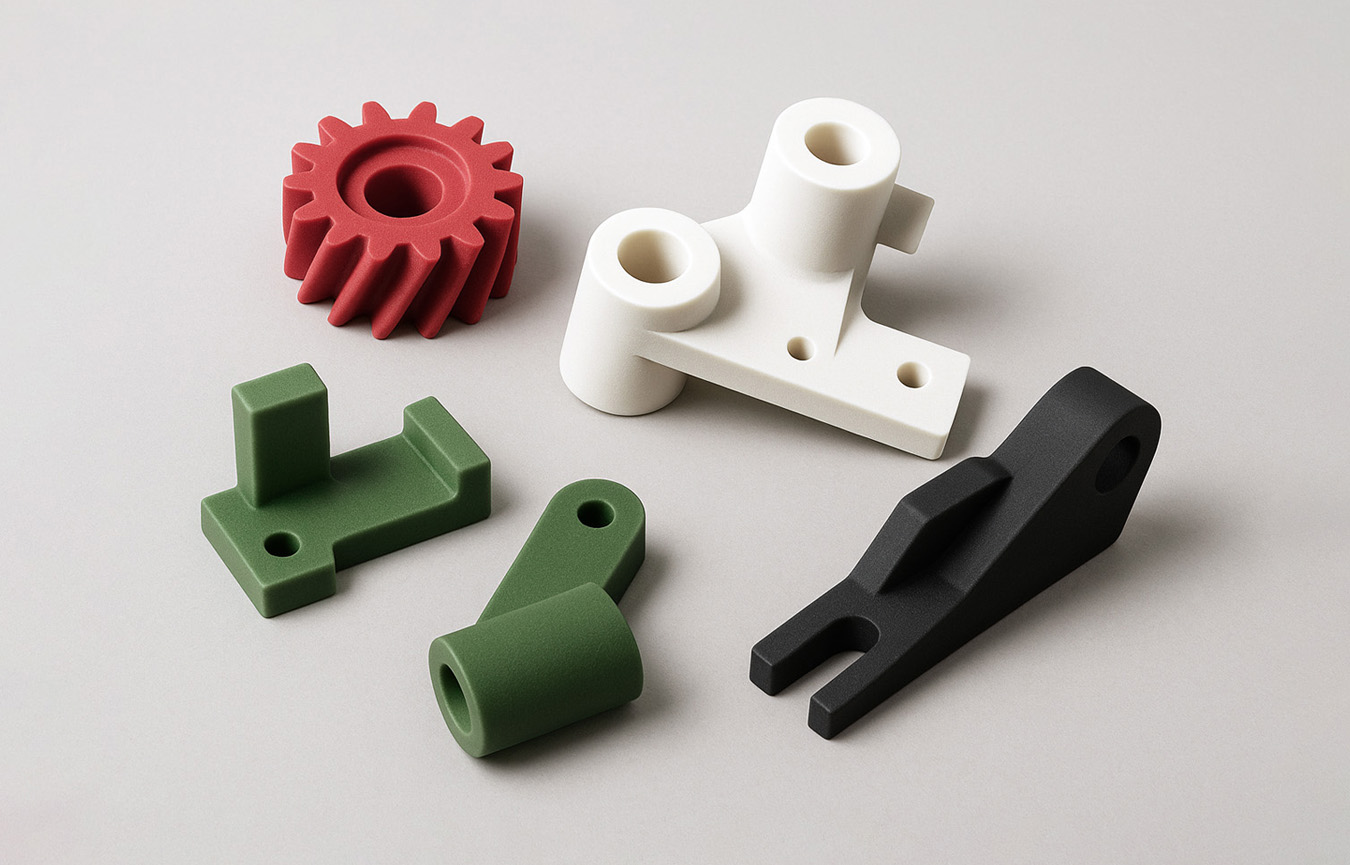

FDM Filament

FDM (Fused Deposition Modelling) 3D printing is an additive manufacturing technology that creates three-dimensional objects from a digital model. The process involves extruding a thermoplastic filament, such as PETG, TPU, PLA or ABS, which is heated and deposited layer by layer to build the desired shape. We use this technology for rapid prototyping and the production of custom-made parts.

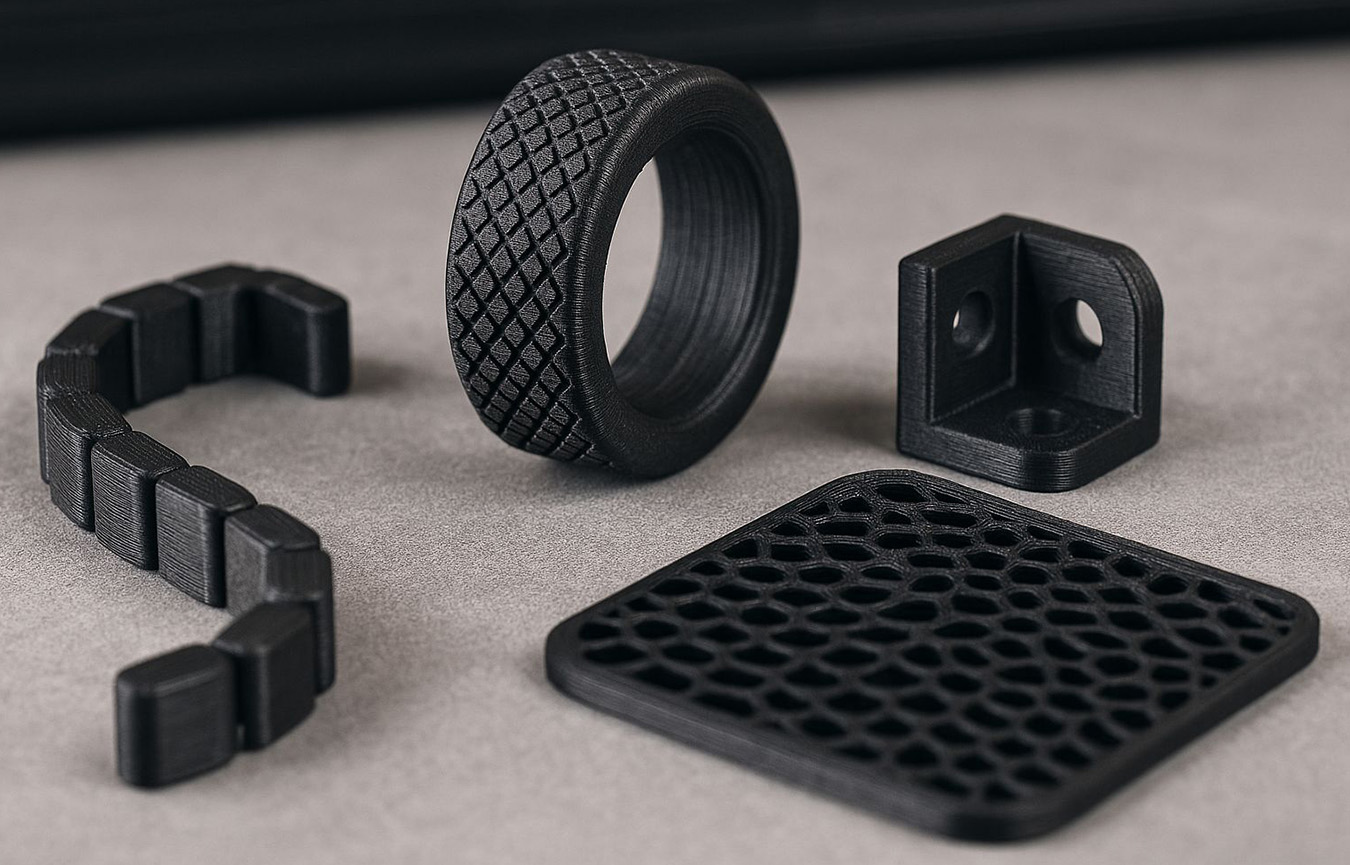

TPU 85A

Flexible filament designed to simulate rubber and soft silicone.ABS

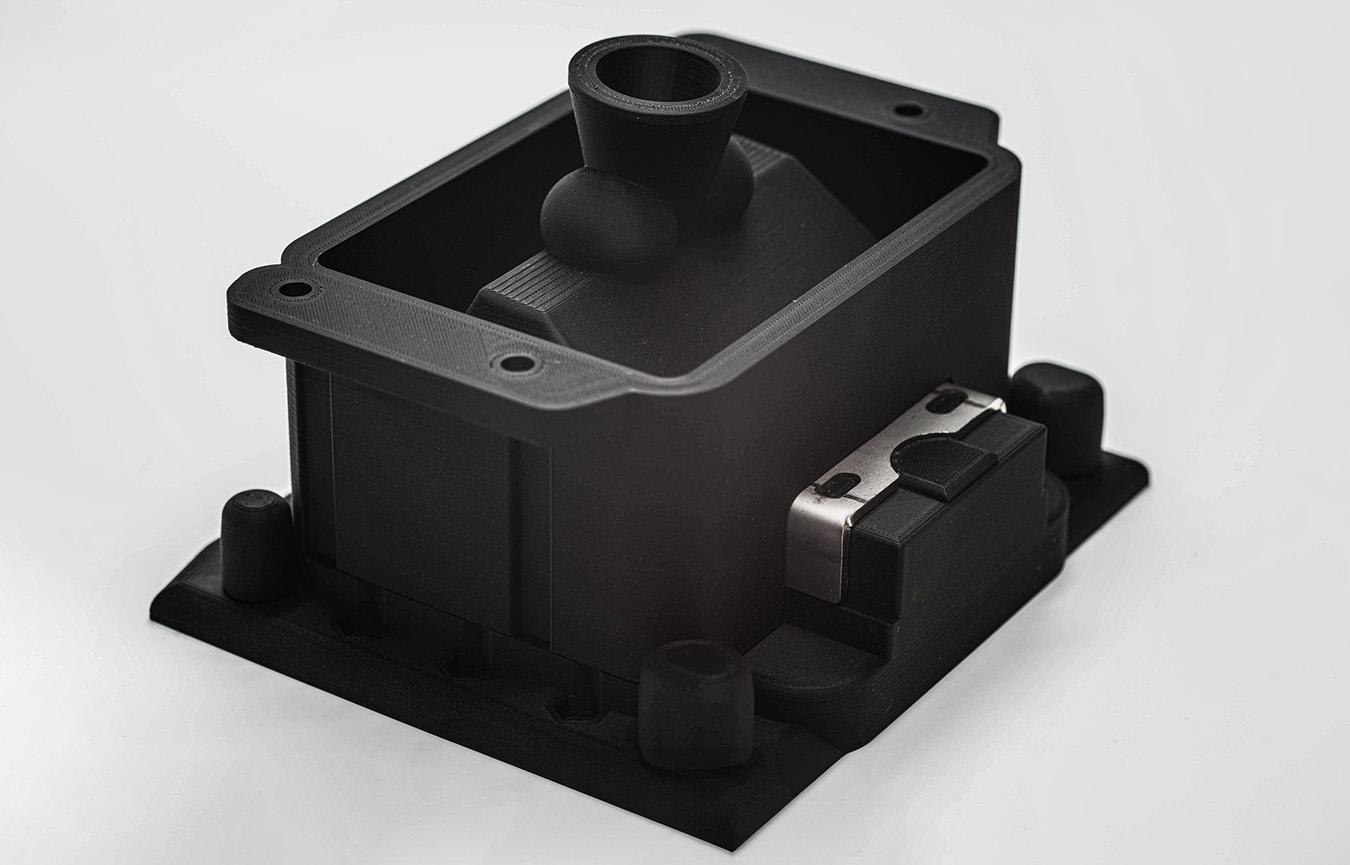

Technical polymer with high thermal, impact, and weather resistance.